Today we’ll be taking a look at backflow preventer vs check valve – two of the most important components of a plumbing system. Let’s wade through this murky water and figure out what exactly sets these two apart.

Check Valve vs Backflow preventer

A check valve is typically used on pumps, such as sewage ejector systems and domestic water booster pumps, because it prevents reverse flow at outlets by providing an internal relief mechanism. It also helps regulate fluid levels by allowing fluids to build up behind it instead of flowing freely backward into another pipe or vessel when no power is available to hold back pressure on its own during shut-off periods. Check valves have simple designs that make them relatively easy to install and maintain over time which makes them ideal for residential use.

Backflow preventers and check valves are important elements of a pipe system, as they play a vital role in maintaining the integrity of the plumbing. Their purpose is to allow fluids or gases to flow in one direction only, thus helping to control and protect the flow of water. Understanding the differences between a backflow preventer and a check valve is key for installing a reliable system for your home or business.

A backflow preventer is an assembly consisting of multiple check valves, shut off valves, and other components designed to help reduce flooding from backflow. It prevents water from flowing backwards into the drinking water supply due to changes in pressure which could otherwise occur within pipes running between different buildings. It ensures that water flows in only one direction thereby preventing contamination of the freshly supplied fresh water with potentially hazardous chemicals or biohazards that might exist further down the piping supply line.

What is a Backflow Preventer Used For?

A backflow preventer is a mechanical device installed in plumbing systems to prevent contaminated water from flowing into the drinking-water supply. This device operates by blocking backward flow between a public water supply and a private property’s water system. Contaminated water could contain hazardous chemicals, solvents, pesticides, fuels and other pollutants. Backflow preventers ensure that only potable water enters a home or building’s plumbing system.

The most common type of backflow preventer is the double-check valve assembly (DCVA). This device contains two independent check valves in series, which are monitored with test cocks for checking if they both remain closed when flow reversal is initiated under any conditions.

In addition to DCVAs, other types of backflow preventers include:

- Reduced pressure zone devices (RPZs) – certified components designed to protect potable installations from contamination due to backsiphonage or backpressure.

- Atmospheric vacuum breakers (AVBs) – used in non-potable installations such as lawn irrigation systems.

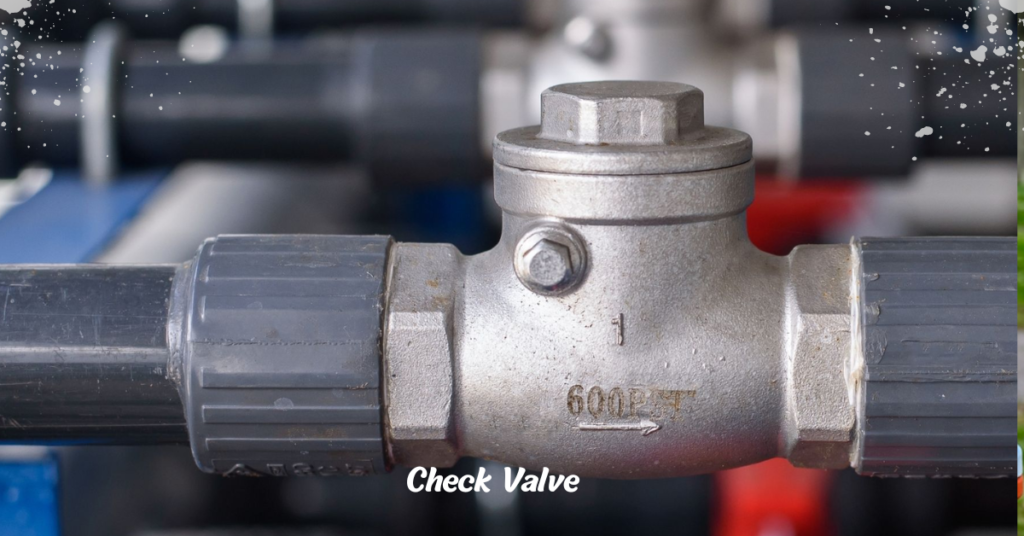

What is a Check Valve Used For?

Check valves, also known as non-return or one-way valves, regulate the direction of flow in pipes and pipelines. The valve type allows fluid to travel through a pipe in one direction but closes and prevents flow in the opposite direction. By doing so, check valves not only stop backflow but also reduce pressure losses and ensure full system performance in piping systems.

The two most common types of check valves are swing check valves and ball/disk check valves.

- Swing check valves feature hinged plates or flap discs that open when flow is in the right direction and close with backflow; when closed, these components create a drop seal that prevents backflow.

- Ball/disk check valves contain a hollow perforated ball or a flat disc mounted on a spring-loaded piston or spindle. When pressure from upstream causes sufficient force against the piston/spindle, it opens the valve allowing liquid to pass; conversely, if this process is reversed it will close automatically due to the internal spring component stopping any reverse flow.

Is a Check Valve a Backflow Preventer: Similarities between Backflow Preventer and Check Valve

Backflow preventers and check valves are both pressure relief devices that help regulate the pressure in a closed system by allowing for fluid to escape if it reaches a certain level. While backflow preventers and check valves both perform the same basic task, they have some key distinctions which can make them better suited to different applications.

The primary similarities between a backflow preventer and check valve is that they both control backpressure in order to ensure safe operation of pumps, compressors, vessels, boilers, and other systems. Additionally, they can be used in many different industries including manufacturing, oil & gas refining, chemical processing and water/wastewater treatment applications. Lastly, both devices are available in various sizes depending on the specific application requirements.

Regarding differences between the two devices; while they may have similar construction and operational characteristics (such as flapper/flapperless design or spring loaded closing mechanism), a major distinguishing trait of backflow preventers is their ability to stop bi-directional flow from occurring – hence their name – while the chief purpose of a check valve is to reduce high-pressure incidents from occurring due to flow going “downhill” towards lower-pressure areas. Another difference between the two types of relieving devices is that backflow preventers employ non-return pinch or swing clapper designs but check valves must feature rigid valve member designs such as gates (lift type or parallel slide) or discs (swing or tilting).

Both types of pressure relief valves are important components for maintaining safe working conditions for personnel as well as protecting expensive equipment in order to avoid costly repairs or even catastrophic failure scenarios such as excessive pump cavitation damage due to underperformance caused by insufficiently relieved head pressures. Ultimately, determining which device best suits your case ultimately depends upon your exact requirements – ask an expert who will be able to recommend safest option based on your specific situation!

Difference between Backflow Preventer and Check Valve

Backflow preventers and check valves are devices that help to protect systems from the risking effects of backflow. Backflow is the flowing back of wastewater and other liquids into the public water system, posing a significant risk for contamination in drinking water supplies.

Both backflow preventers and check valves are used to help contain and control contamination of public and private water systems as they block reverse flow while allowing liquids to pass through in one direction.

The main difference between a backflow preventer and a check valve is in their design capabilities. While both types of valves are designed to contain fluid in one direction, only a backflow preventer can withstand higher levels of pressure and flows, whereas a check valve is designed for lower levels of pressure or flows. Backflow preventers also have the capacity for atmospheric venting which maintains balance between air pressure on opposing sides of the preventive device, further enhancing its design capabilities over those available with a check valve.

The specific type of backflow prevention device used depends on the application at hand; however, both devices have their place in protecting drinking water from contaminants caused by reverse flow.

Common Applications of Backflow Preventer and Check Valve

Backflow preventers and check valves are often used in plumbing systems to control the flow of water throughout the system. While both serve similar purposes and are similar in design, there are a few differences that can help you determine which of these two devices is best for your needs.

Backflow preventers are designed to protect drinking water from contamination by preventing the flow from entering into higher pressure systems. Common applications include home gardening and lawn irrigation systems, boiler systems, and industrial manufacturing processes. Check valves, on the other hand, provide one-way protection against fluid and vapors flowing back into equipment that can cause damage or malfunction. Examples include preventing air entering a pump or escaping a tank along with protecting laboratory piping among others.

Common applications of backflow preventers include:

- Drinking water outlets such as shower heads, faucets, dishwashers and other fixtures connected to public water supplies;

- Boilers with unattended filling operations;

- Fire protection systems like dry sprinkler reservoirs;

- Gardens with an outside tap connected directly to potable-grade water supplies;

- Compressed air lines used in industrial plants.

Check valves can be found in numerous plumbing applications but some of their common uses include steam traps, condensate pumps, heat exchangers and instrumentation pilot lines along with providing protection for equipment in chemistries such as sulfuric acid or where ammonium nitrate is stored or handled.

Advantages and Disadvantages of Backflow Preventer and Check Valve

Backflow preventers and check valves are both considered as backflow prevention devices and are designed to ensure that fluids flow in one direction in a piping system. Both devices help to stop unwanted water from flowing in the opposite direction, thus preventing contamination and other problems. While both of these devices are similar, they have significant differences between them.

Advantages of a backflow preventer include the following:

- Controls pressure by allowing fluid to flow only in one direction.

- Prevents buildup of water containing contaminants, chemicals, or sediment from entering into a piping system; thus safeguarding lines against health hazards posed by these materials.

- Reduces maintenance costs as it requires seeking out only occasional cleaning services as needed compared to regular scheduled maintenance with check valve models.

Disadvantages of a backflow preventer include:

- The expense associated with this device is considerable due to its complex design and models that need multiple components for its function.

- It is prone to damage since it contains several moving parts that can get compromised over time.

Advantages of a check valve include:

- The incorporated design is simpler compared to the complicated multi-component setup of the backflow preventer model and is friendly on budgets as it does not cost nearly as much money for installation or upkeep requirements.

- Check valves last longer since there are fewer components than those with the more complicated setup like a backflow preventer involves and therefore has overall less chance for malfunctioning down the road.

Disadvantages of check valves include:

- Check valves do not offer controlled pressure relevant levels necessary for some industrial settings; this lesser regulation leaves openings vulnerable towards external contaminants’ invasion if it is inadequate enough at maintaining the pressure balance required to block any external threats away from entering into the system itself.

- Given its simple design, regular maintenance is often mandated at specified intervals or else lines might flush open on their own, allowing contaminated material into them if left unchecked without periodic service calls made.

Double Check Valve vs Backflow Preventer

Both a double check valve and a backflow preventer are types of devices used to prevent the backflow of water or other fluids in plumbing systems. While they serve a similar purpose, there are some differences between them.

A double check valve is a type of backflow prevention device that consists of two check valves arranged in series. Check valves allow flow in one direction but prevent backflow in the opposite direction. In a double check valve assembly, the two check valves work together to provide an extra layer of protection against backflow. This type of device is commonly used in low-hazard applications, such as irrigation systems or residential plumbing.

On the other hand, a backflow preventer is a broader term that encompasses various types of devices designed to prevent the reverse flow of fluids. These devices can include double check valves, but they can also incorporate other mechanisms such as pressure differentials or air gaps. Backflow preventers are typically used in more critical applications where the risk of contamination or cross-connection is higher, such as in commercial or industrial settings.

Is a double check valve the same as a backflow preventer?

A double check valve and a backflow preventer are similar in that they both prevent contaminated water from flowing back into the main water supply. However, they are not exactly the same thing.

A double check valve is a type of backflow preventer that is used in situations where there is a low to moderate risk of contamination, such as in residential or commercial buildings. It works by using two valves to prevent water from flowing back into the main water supply.

On the other hand, a backflow preventer is a broader term that can refer to various types of devices used to prevent backflow, including double check valves, but also including other types of valves and devices. So, while a double check valve is a type of backflow preventer, not all backflow preventers are double check valves.

Can a check valve be used as a backflow preventer?

A check valve can be used as a backflow preventer in certain situations, but it is not always recommended. A check valve is designed to allow water to flow in only one direction, which can help prevent backflow to some extent. However, it is not always reliable in preventing backflow, particularly if the pressure differential between the two sides of the valve is not significant.

Moreover, a check valve is typically not sufficient in situations where there is a high risk of contamination, such as in industrial or commercial settings. In such cases, a more robust backflow preventer, such as a double check valve or a reduced pressure zone (RPZ) backflow preventer, is necessary to ensure the safety of the water supply.

Non Return Valve vs Backflow Preventer

A non-return valve and a backflow preventer are both devices used in plumbing systems to prevent the backflow of fluids, but they differ in their design and functionality.

A non-return valve, also known as a check valve or a one-way valve, is a simple valve that allows fluid to flow in one direction while preventing it from flowing back in the opposite direction. It typically consists of a hinged flap or a spring-loaded disc that closes when the flow direction reverses, thus preventing backflow. Non-return valves are commonly used in a variety of applications, such as household plumbing, irrigation systems, and industrial pipelines, where backflow prevention is necessary but the risk of contamination is relatively low.

On the other hand, a backflow preventer is a more comprehensive device that provides a higher level of protection against backflow and potential contamination. It typically incorporates multiple mechanisms to prevent the reverse flow of fluids. A backflow preventer may include a combination of check valves, pressure differentials, air gaps, or other mechanisms depending on the specific requirements of the plumbing system.

Conclusion

In conclusion, both backflow preventers and check valves can serve the same purpose of blocking backwards flow, reducing the risk of fluid mixing between two connected systems. However, for highest level of reliability and protection, a backflow preventer is superior as it provides dual barrier protection with a mechanical valve and potential sensors that detect when pressure drops or rises, allowing them to automatically control the release of contaminated water.

Check valves provide an economical solution that is still capable of blocking backflow and should be adapted when large flow rates are not required.

Frequently Asked Questions

What is a backflow preventer?

A: A backflow preventer is a device used in a plumbing system to prevent backflow. It is designed to allow water to flow in one direction only and to prevent the flow of water in the opposite direction.

What is a check valve?

A: A check valve is a mechanical device used in a plumbing system to prevent water from flowing in the opposite direction. It is designed to allow water to flow in one direction only and to prevent the flow of water in the reverse direction.

What is the difference between a backflow preventer and a check valve?

A: The main difference between a backflow preventer and a check valve is that a backflow preventer is designed to prevent backflow from occurring in a plumbing system, while a check valve is designed to allow water to flow in one direction only and to prevent the flow of water in the reverse direction.

What is another name for check valve?

A: A check valve is also commonly referred to as a non-return valve, one-way valve, or clack valve. These names all refer to the same type of valve that allows water to flow in only one direction.

What are the 5 types of check valves?

A: The five types of check valves are:

- Swing check valve: uses a hinged disc to allow flow in one direction and prevent backflow

- Lift check valve: uses a piston-like disc to allow flow in one direction and prevent backflow

- Diaphragm check valve: uses a flexible diaphragm to allow flow in one direction and prevent backflow

- Ball check valve: uses a ball to allow flow in one direction and prevent backflow

- Stop-check valve: combines features of a stop valve and a check valve, allowing for both shutoff and prevention of backflow.