There are different types of pipe fittings used in plumbing, which is an essential service covered under the umbrella of MEP services. This blog post is about pipe fittings, materials used, their uses, applications and standards used in the plumbing system.

What are Pipe Fittings?

Plumbing pipe fittings connect/join pipes together in order to increase the length or redirect the flow of the water supply. They help in building various plumbing configurations as per requirement. Pipe fittings come in a range of sizes to fit the pipe they will attach to and are used to combine, divert, or reduce the flow of the water supply.

There are size guidelines to follow, and pipe fitting specifications are crucial. Some types of pipe fittings are made with different-sized pores and act as the transition from one size pipe to another. However, the majority of pipe fittings have openings that are the same size on both ends. In plumbing systems, these pipe fittings are used as pipe connectors for multiple purposes like flow regulation or flow measurement.

Pipe Fitting Material

Plumbing services have different types of pipe fittings and they are made of various materials. Some are made of metal, while others are made of plastic. Copper, aluminum iron, brass, PVC, and other materials are available for plumbing pipe fittings, and the optimum option for your network will rely on the pipes you use as well as on flexibility, cost, environmental factors, and required pressure ratings. We have divided the list of pipe fitting materials into metal and various plastics to make it easier for you to select the right one.

Copper:

Copper has excellent thermal conductivity, and it can withstand high temperatures. This makes copper fittings ideal for boilers and other hot water systems. Because copper is a good conductor of heat, it is a good choice as pipe fitting material in residential water supply lines. Copper also has the ability to resist corrosion and is resistant to the buildup of scale. Because copper is a good conductor of heat, it will easily transfer heat from one point to another.

Aluminum:

This material is very flexible and does not require additional support. Because it is light, it will not weigh down the pipes and is best-used fitting with aluminum pipes. Its thickness is uniform, and it has good thermal conductivity. It is also easy to work with and is available in a variety of sizes. Aluminum is an extremely popular material because it is both durable and corrosion-resistant. It is lightweight and easy to cut, and it can be easily welded.

Cast Iron Fittings:

Cast iron fittings are the most common type of pipe fittings available. These are used for sewer and drain piping in both residential and commercial buildings. Cast iron fittings are made of iron and they come in a variety of sizes and shapes.

The cast iron fittings are used for various purposes. For example, they are used for sanitary piping in the bathroom and kitchen.

Steel/Stainless Steel:

If you want to make your pipes stronger, you should use stainless steel instead of iron pipes. Iron pipes can break easily and they may rust when they get wet. You can use stainless steel for both commercial and residential purposes.

Stainless steel is easy to install, and you don’t have to worry about rusting. You can also use stainless steel for sanitary purposes. Steel pipes are durable and they can withstand a lot of heat.

Brass:

Brass fittings have a high resistance to corrosive substances. They are also resistant to high temperatures and extreme pressures. Brass is also easy to work with and can be readily machined and fabricated into various types of tubing and piping. Brass fittings are often used in the plumbing industry for connecting pipes and tubing.

Nylon:

A lot of people prefer using nylon pipe fittings over brass pipe fittings because of its high strength. Nylon is a great material to use when working with piping. Brass fittings aren’t as popular as nylon ones. Nylon is a very strong material and it’s very resistant to heat and cold. It can also withstand chemicals and abrasive materials.

PVC Pipe Fittings:

PVC (Poly Vinyl Chloride) pipe fitting is a very useful material for plumbing. It is a versatile material that you can use in a variety of ways. It is a hard plastic that is suitable for use with various pressure ratings. Fittings are linked to PVC using threads or solvent welding to meet supply and drainage requirements as well as to distribute hot and cold water.

ABS, also known as acrylonitrile butadiene styrene, is a stiff, black pipe plastic that functions similarly to PVC but is frequently seen as more cost-effective.

Polyethylene:

PE (Polyethylene) is a polymer of ethylene. It has a low density and low specific gravity and is flexible. PE is resistant to ozone and sunlight. It has excellent resistance to acids and alkalis. Polyethylene is very versatile, and it can be used for many purposes. It can be used for pipes, tanks, valves, fittings, and pipes in buildings.

Polypropylene:

Polypropylene (PP) pipe fittings are very popular among builders because of their low cost. The material is durable and long-lasting PP has many advantages. It is easy to work with and can be recycled. PP pipe fittings are available in a variety of sizes, forms, and colors. This thermoplastic is used in exposed applications and is excellent for cold water flow and yield elongation.

Plumbing Pipe Fittings Forms

There are two basic forms used in different types of pipe fittings, male and female.

The male fittings come with a tapered end that will screw into the female fitting. The female fittings are attached to a pipe with a flanged end that screws into the male fitting. The male fittings are used to connect the pipes that are located at the same level while the female fittings are used to join the pipes located above or below.

Types of Pipe Fittings and Their Uses in Plumbing

Most people are familiar with some types of pipe fittings. But do you know what each of them does? Are you sure about what each fitting in the plumbing system is used for? It is important to know the exact purpose of different types of pipe fittings. If you can’t identify the function of the fittings in your home, it is best that you call a professional plumber. In general, you can use the following information to help you identify which type of fitting should be used.

There are many different types of pipe fittings, including elbows, couplings, valves, and caps, each of which has a specific function. We’re going to look at each one below to assist you choose the fitting that will work best for your pipes.

1. Elbow Pipe Fittings

The elbow fitting is one of the most common under the umbrella of types of pipe fittings in residential and industrial applications. It is also known as a bend in some cases. It is used to connect two pipes with the same nominal diameter or different nominal diameters and to turn the pipe and subsequently the fluid direction in a 45-degree or 90-degree direction. A common use of elbow fitting is in the construction of a fire sprinkler system.

When you install a water line, it is important that you use the right elbow pipe fittings. This helps prevent the formation of clogs that can block the pipes. It is important to note that elbows are made from steel and aluminum.

2. Cross-Pipe Fitting

Four pipes are connected together using cross-pipe fittings. It is also known as a four-way fitting or a cross-branch line in plumbing. A solvent-welded socket or female-threaded ends are frequently present on pipe crosses that have one inlet and three outlets or three inlets and one outlet.

Due to their location in the middle of four connection points, cross fittings may cause pipes to become stressed as temperatures fluctuate. Both the inlet and the outlet can have the same diameter as well as various diameters. This means that both the straight cross and the decreasing cross are available.

3. Tee (T) & Wye (Y) Pipe Fittings

A fitting or connector known as a pipe tee is used to connect two or more plumbing pipes. These fittings, which are characterized by their T-shaped form, attach the two pipes or tubes at a 90-degree angle. Generally speaking, tees are used to combine or split a fluid flow.

In piping, equal/straight tees and reducing/unequal tees are both employed. Equal/straight tees have identically sized inlets and outlets. On the other hand, reducing/unequal tees have different inlets and outlets size.

Wye pipe fittings, also known as “lateral connections”, attach one pipe to another at an angle. These pipe fittings are Y-shaped, as their name suggests. Three openings that are connected to one another at 45-degree angles make up Wye pipe fittings.

4. Reducer Pipe Fittings

Reducers have a small diameter and can be used in larger pipes to connect two points. Reducers allow water to flow from the larger pipe to the smaller pipe or vice versa. A reducer fitting has an inner male and outer female connector. The reducer has a smaller diameter than the pipe it fits in and is located inside a pipe fitting with a larger diameter. For example, a 1/2″ reducer pipe may be installed in a 3″ pipe.

If you want to increase the flow rate of your water system, you should install reducers. Reducers are used in various plumbing systems for increasing the efficiency of the system.

5. Union Pipe Fittings

A pipe union is a particular kind of fitting device made to connect two pipes together without affecting the functionality of either one. A pipe union is basically a mechanism that holds two pipes together. It can be inserted into two pipes and held in place with screws and nuts. A pipe union will usually come with extra washers and other pieces that allow it to connect securely.

You will also have to tighten it to make sure the pipes are held together and the union doesn’t come apart. Pipe unions are used to create connections for all small-diameter piping systems that need to be secure and simple to assemble and disassemble.

6. Adapter Pipe Fittings

An adapter in plumbing is typically a fitting that connects two dissimilar pieces. Any fitting that joins pipes made of various materials is usually referred to as adapter pipe fitting. It allows the two ends to fit snugly together without touching each other. The adaptor is used to prevent leaks and maintain the fluid-tight seal.

7. Bushing Pipe Fittings

The bushing is a pipe fitting that connects two pipes of various sizes. A bushing has internal and external threading. The bushing’s bigger diameter can fit inside the larger pipe. The smaller pipe is next placed into the bushing’s smaller end.

8. Coupling Pipe Fittings

A coupling pipe fitting, used in plumbing, is a very short piece of pipe. It has a socket or female thread at one or both ends, which allows two pipes of the same size or different diameters to be connected together. Pipe fittings called couplings are used to extend or end pipe runs.

9. Olet Pipe Fittings

Olet fittings, also known as branch connection fittings or outlet fittings, allow a larger pipe to flow into a smaller pipe (or one of the same size) at 45 or 90 degrees from a run pipe (also known as a header pipe) to a branch pipe (outlet pipe). Weldolet, Thredolet, Sockolet, Latrolet, Elbolet, Nipolet, and Sweepolet are examples of common branch fitting kinds.

10. Trap Pipe Fittings

A trap fitting is a U-shaped section of pipe used in plumbing that is intended to catch liquid or gas to stop the unwanted flow. Most notably They prevent sewage gases from entering buildings while still allowing waste to pass through.

11. Cap Pipe Fittings

Pipe cap fittings are mostly used to waterproof the connections. Additionally, they are employed to seal the extremities of hydraulic or pneumatic pipelines and tubes. They are utilized in machinery, processing equipment, and plumbing systems for home, commercial, and industrial water supply lines.

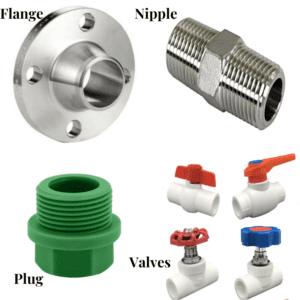

12. Flange Pipe Fittings

The most extensively used type of pipe fittings is the pipe flange. Two pipes are mechanically joined together using a flange. The mechanical joining of a pipe to a tee, valve, choke, or any other piece of apparatus is also possible. Round, square, and rectangular flanges are all readily available.

13. Nipple Pipe Fittings

A nipple is a fitting that is a brief section of pipe when it comes to plumbing and piping. When connecting piping to threaded fittings, valves, or equipment, a nipple is typically provided with a male pipe thread connection at each end of the fitting.

14. Plug Pipe Fittings

Pipe plug fittings are the cap end of fractional tubes, which are employed in many different sectors. To stop the flow, place these pipe plugs into the end of the tubing. High-quality tube plugs with a range of end connections are made from a variety of materials.

Valves in Pipe Fittings

Pipe fittings are parts used to connect pipe segments to one another or to other fluid control devices (such as pumps and valves) when building pipelines. A form of pipe fitting called a pipe valve is used to regulate the flow of fluid through a pipeline.

Pipe Fittings Connection Types

In order to meet the needs of different industries, Pipe Fittings Connection provide various types of pipes, valves, and fittings. In terms of connections, BFO provides a variety of types to satisfy all end connection requirements. They include compression, butt weld, groovy end (mechanical fittings), flanged, flared, and threaded fitting.

Threaded pipe fittings can be used to connect pipes and other fittings together. They can also be used to connect pipes together. A threaded fitting is made up of two parts: the outer shell and the inner core. The inner core is smaller than the outer shell. This means that the inner core will fit into the space between the inner walls of the outer shell.

A primer and quickly drying solvent cement are used to attach plastic pipes and fittings that have smooth walls and can easily slide together. Solder is melted, or “sweated,” along the seam of brass or copper fittings and pipes to create permanent, leak-free pipe connections.

In clamp fitting, after the fitting has been placed, the clamp is tightened around the pipe. While in crimp fittings, after the fitting has been fitted, a metal ring is securely squeezed, or crimped, around the pipe. On the other hand, in flared fitting, after the pipe has been “flared” using a special tool, the flare nut and the cone-shaped fitting join the pipe and fitting in high water pressure and gas applications.

Applications/Uses of Pipe Fittings

In power generation, pipe fitting installation can be used to create a water seal around the equipment that allows hot water to reach the condenser coil.

Oil and gas industry involves pipe fittings being connected to each other for delivering oil to different stations along the pipeline.

Other major areas for pipe fitting applications are: Food and beverage, refinery, chemical, and petrochemical, municipal which refers to water lines, sewage lines, drainage, and fire sprinkler systems, irrigation, residential, ventilation, marine and dredging

How to Choose Pipe Fittings?

When you are trying to buy a pipe fitting, you must consider a few other factors. You must first know the materials used in the pipe and fitting you want to buy. The type of pipe you want to use before you can make the right selection must be known. You should also be familiar with standards and codes for fittings.

One must also know the pressure rating of the pipe and the end connection type. You need to know the type of fittings you want to use and the sizes of the pipe you want to connect. This information is very important when you are trying to buy a pipe fitting. This is why it is important to learn about the different types of pipe fittings.

Pipe Fitting Standards and Codes

In all the types of pipe fittings, standards and codes play a vital role. The manufacture and installation of pipe fittings is tightly regulated by various standards and codes.

The integrity of all the types of pipe fittings and flanges in the piping system depends on various principles used in design, construction and maintenance of the entire system. The components of pipe fittings are made in different materials, in a variety of types and sizes and hence should be manufactured according to common national standards or according to manufacturers’ proprietary item. Some manufacturers also use their own internal piping standards based upon national and industry sector standards.

Piping codes imply the requirements of design, fabrication, use of materials, tests and inspection of various pipe and piping system. It has a limited jurisdiction defined by the code. On the other hand, piping standards imply application design and construction rules and requirements for pipe fittings like adapters, flanges, sleeves, elbows, union, tees, valves etc. Like a code, it also has a limited scope defined by the standard.

Common Pipe Fittings Standards

Some widely used standards available for different types of pipe fittings are as follows:

| The American National Standards Institute (ANSI) American Society for Mechanical Engineers (ASME) | – The following are the ASME/ANSI B16 standards for various pipe fittings: • ASME/ANSI B16.1 – 1998 – Cast Iron Pipe Flanges and Flanged Fittings • ASME/ANSI B16.3 – 1998 – Malleable Iron Threaded Fittings • ASME/ANSI B16.4 – 1998 – Cast Iron Threaded Fittings • ASME/ANSI B16.5 – 1996 – Pipe Flanges and Flanged Fittings • ASME/ANSI B16.11 – 2001 – Forged Steel Fittings, Socket-Welding and Threaded • ASME/ANSI B16.14 – 1991 – Ferrous Pipe Plugs, Bushings and Locknuts with Pipe Threads • ASME/ANSI B16.15 – 1985 (R1994) – Cast Bronze Threaded Fittings • ASME/ANSI B16.25 – 1997 – Buttwelding Ends |

| American Society for Testing and Materials (ASTM International) | • ASTM standards encompass a variety of metal pipes, tubes, and fittings for regular usage, specific applications like fire protection, and high-temperature use. • The 67 volumes that makeup 16 sections of the ASTM standards are released. |

| British Standard Pipe (BSP) | • The pipe fitting standard in the United Kingdom is known as BSP. • Using an external (male) and an internal (female) thread to connect and seal pipe ends is referred to as this family of common screw thread types. |

I hope this knowledge about types of pipe fittings will help you in selecting the right pipe fitting for your need.

Expert Opinion – Types of Pipe Fittings and Their Uses

As an MEP engineer with extensive experience in plumbing systems, I can attest to the importance of understanding the various types of pipe fittings and their specific uses. Pipe fittings play a crucial role in creating a well-functioning plumbing system by connecting pipes, redirecting flow, and accommodating changes in direction or diameter.

From my professional standpoint, it is vital to select the appropriate type of pipe fitting for each specific application. Whether it’s a coupling, elbow, tee, reducer, or valve, each fitting serves a distinct purpose in the overall plumbing design. For instance, a coupling is used to join two pipes of the same diameter, while an elbow facilitates changes in direction. These fittings enable efficient water distribution, prevent leaks, and ensure the longevity of the plumbing system.

Understanding the nuances of pipe fittings is essential for plumbing professionals and DIY enthusiasts alike. It enables them to make informed decisions and implement effective solutions in various plumbing projects. By considering factors such as material compatibility, pressure requirements, and system layout, one can achieve a reliable and durable plumbing system that meets the specific needs of any building or infrastructure.

FAQs – Types of Pipe Fittings and Their Uses

What are the common types of pipe fittings used in plumbing?

The common types of pipe fittings used in plumbing include couplings, elbows, tees, reducers, and valves. Couplings are used to join two pipes of the same diameter, while elbows are used to change the direction of the pipe.

Tees are T-shaped fittings that allow the flow of water in three directions, and reducers are used to connect pipes of different diameters. Valves are used to control the flow and shut off the water supply when necessary.

How do I select the right pipe fitting for my plumbing project?

Selecting the right pipe fitting for your plumbing project requires considering several factors. First, you need to determine the type of fitting that best suits your specific application, such as a coupling, elbow, tee, reducer, or valve.

Next, consider the material compatibility to ensure the fitting is compatible with the pipes you are using. Additionally, take into account the pressure requirements of your plumbing system and choose fittings that can handle the desired pressure.

Lastly, consider the layout and design of your plumbing system to ensure the fittings will allow for efficient water distribution.

Why are pipe fittings important in plumbing?

Pipe fittings are crucial in plumbing as they allow for the proper connection, redirection, and adjustment of pipes. They ensure a secure and leak-free connection between pipes, enabling efficient water distribution and preventing costly water damage. Pipe fittings also accommodate changes in direction, allowing the plumbing system to navigate around obstacles and reach various areas of a building or infrastructure.

Additionally, fittings like valves provide control over the water flow, allowing for maintenance, repairs, and shut-off when necessary. Overall, pipe fittings are essential components that contribute to the functionality, reliability, and longevity of a plumbing system.

Can I use different types of pipe fittings together in a plumbing system?

In certain cases, it is possible to use different types of pipe fittings together in a plumbing system. However, it is important to ensure compatibility and proper installation. Mixing different types of fittings may require the use of adapters or transition fittings to connect pipes of different materials or sizes.

It is recommended to consult with a professional plumber or refer to plumbing codes and standards to ensure compliance and proper functionality of the system when using different types of fittings together.

Are there specific maintenance requirements for pipe fittings in a plumbing system?

While pipe fittings generally require minimal maintenance, it is important to periodically inspect them for any signs of leaks, corrosion, or damage. Regularly checking fittings can help identify potential issues early on and prevent more significant problems down the line. It is also essential to ensure that fittings are tightened properly and not overtightened, as this can cause damage.

Additionally, if any modifications or repairs are made to the plumbing system, it is crucial to use compatible fittings and follow proper installation guidelines to maintain the integrity and functionality of the system.

Amazingly good article.

Thank you Vipul for your kind feedback.