Are you planning to calculate electrical load estimate for a new home or office space? It is an important step in the construction process for the building. This ensures that the electrical system is properly designed and sized to meet the needs of the occupants. In this blog post, we’ll go over the steps for how to calculate electrical load estimate for your building.

What is an electrical load?

Before we start, let’s understand what an electrical load is. An electrical load refers to the amount of electrical power that is being used by a device, system or facility at a specific point in time. It is measured in units of power, such as watts (W) or kilowatts (kW). The size of your electrical service panel is based on this calculation.

Electrical loads can be classified into different categories, such as:

- Resistive loads: These are loads from devices that convert electrical energy into heat, such as electric space heaters and toasters.

- Inductive loads: The loads from devices that use electromagnetic fields, such as motors and transformers.

- Capacitive loads: These are loads from devices that store electrical energy, such as capacitors used in motor starters, buried cables and capacitor banks.

- Transformer loads: Loads from devices that change the voltage level of an electrical circuit, such as transformers.

Basic types of electrical load in buildings

In order to calculate the electrical load for your home or building, it is important to get familiar with some basic types of electrical loads.

These are loads that need to be considered when estimating your electrical needs of building.

Continuous loads:

Continuous loads run non stop, such as refrigerators, air conditioners, and dehumidifiers. They require a steady and continuous supply of power.

Non-continuous loads:

These loads run for short periods of time, such as washing machines, dishwashers, and microwave ovens. They require a surge of electrical energy when they are turned on, and then settle into a lower level of energy usage.

Lighting loads:

These are loads that are associated with lighting fixtures, such as incandescent bulbs, fluorescent lamps, and LED lights. Lighting loads can vary significantly depending on the type of lighting used, the number of fixtures, and the hours of use.

Momentary loads:

These are loads that require a short, but intense surge of electrical energy, such as power tools, electric drills, and vacuum cleaners.

HVAC loads:

These are electric loads that are associated with heating, ventilation, and air conditioning systems.

Motor loads:

These are loads that are associated with electric motors, such as those used in pumps, fans, and compressors.

Receptacle loads:

These are loads that are powered through electrical outlets, such as televisions, computers, and other small appliances.

Special purpose loads:

These are loads that are associated with specialized equipment, such as medical equipment, laboratory equipment, and industrial machinery.

Also Read: How to Calculate Cooling Load

What is an electrical load estimate and why is it important?

An electrical load estimate is a calculation of the electrical demand that a building or structure will place on the power supply. It is important to accurately calculate electrical load for a building because it ensures that the electrical system is properly designed and sized to meet the needs of the occupants. If the electrical load is not properly calculated, it can lead to issues such as overloaded circuits, power outages, and even fires.

Understanding the Three Aspects of Electrical Load Calculations

Electrical Power Requirement:

Electrical power requirement refers to the amount of power needed to operate individual electrical devices or appliances. It is measured in watts (W) or kilowatts (kW) and indicates the rate at which energy is transferred or consumed by a particular device. Calculating the power requirement of each appliance allows you to understand its energy consumption and make informed decisions about energy-efficient usage.

Electrical Load:

Electrical load refers to the total power demand of all connected electrical devices and appliances at any given time. It is measured in kilowatts (kW) or kilowatt-hours (kWh) and fluctuates depending on the devices in operation. Calculating the electrical load helps you assess the overall energy consumption and plan the electrical system’s capacity accordingly, ensuring it can handle peak loads without causing disruptions or safety hazards.

Electrical Capacity:

Electrical capacity, also known as electrical service capacity, represents the maximum power that an electrical system or service can handle safely and reliably. It is measured in kilovolt-amperes (kVA) and is a crucial factor in determining the size and capability of your electrical service. Understanding the electrical capacity ensures that your electrical system can meet the power demands without overloading, leading to a safe and efficient electricity supply.

Comparison among Electrical Power Requirement, Electrical Capacity, and Electrical Load

| Aspect | Electrical Power Requirement | Electrical Load | Electrical Capacity |

|---|---|---|---|

| Definition | Power needed to operate an individual device or appliance, measured in watts (W) or kilowatts (kW). | Total power demand of all connected devices at a given time, measured in kilowatts (kW) or kilowatt-hours (kWh). | Maximum power an electrical system can safely handle, measured in kilovolt-amperes (kVA). |

| Measurement | Kilowatts (kW) or watts (W). | Kilowatts (kW) or kilowatt-hours (kWh). | Kilovolt-amperes (kVA). |

| Nature | Static value for each device or appliance. | Dynamic, fluctuates based on device usage. | Fixed value for the entire electrical system. |

| Significance | Helps understand energy consumption of individual devices. | Assesses the overall power demand and energy consumption. | Determines the system’s capability to handle loads without overloading. |

How to Calculate Electrical Power Requirement, Electrical Load and Electrical Capacity

- Electrical Power Requirement:

- Use the formula: Electrical Power (W) = Voltage (V) x Current (A).

- Add up the power ratings of all individual devices and appliances to find the total power requirement.

- Electrical Load:

- Sum up the power consumption of all devices and appliances that will be running simultaneously.

- Ensure that the total electrical load does not exceed 80% of the electrical capacity to avoid overloading.

- Electrical Capacity:

- Identify the electrical service size (e.g., 100 amps, 200 amps) and voltage (e.g., 120 volts, 240 volts).

- Use the formula: Electrical Capacity (W) = Voltage (V) x Electrical Service Size (A) x 0.8 (safety margin).

How to Calculate An Electrical Load Estimate for a Building: Step-by-Step Guide

Here are the steps we take in order to calculate a building or a house’s electrical load in Kwh (unit of electricity in electric bills):

A- How to Calculate Power Requirements for a Building

Firstly we find the power requirements of the building.

1. Make a List of Electrical Appliances and Devices

We start by making a list of all the electrical appliances and devices that are to be used in home, including lights, televisions, refrigerators, air conditioners, washing machines, and dryers. Make sure to include any devices that you use frequently, such as computers, smartphones, and other electronics.

2. Determine the Power Requirement of Each Device

Next, we determine the power consumption of each device. You can find this information on the product label or in the manual, or by searching online. Power consumption is usually measured in watts (W) or kilowatts (kW).

Let’s assume a typical US 2 beds house for electrical load calculation.

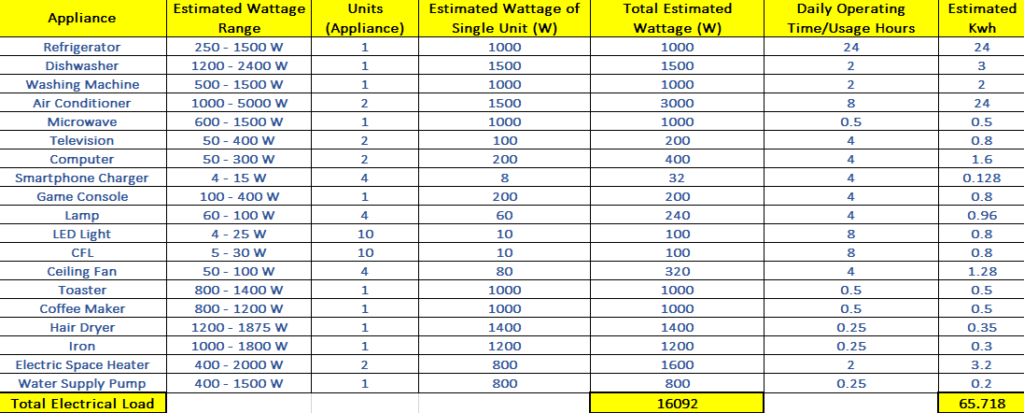

Here is a table of common electrical appliances and devices in a typical US home, along with their estimated electrical load wattage:

Note: These are rough estimates and may vary depending on the brand, model, and usage patterns.

3. Determine the Total Power Requirement

Once we determine the power consumption of each device, then we add up the total power consumption of all the devices on the list. This gives an estimate of the home’s electrical load. Here is how we do it.

Therefore, a typical US home with these appliances and devices would require approximately 16,092 watts of electrical power to operate them simultaneously. It’s important to note that this is only an estimate, and actual electrical usage may vary based on usage patterns and other factors.

B- How to calculate electrical load of a building

We use the power required data in order to calculate the electrical load of a building. In the next step we also take usage time of the appliances into consideration

4. Consider the Operating Time of Each Appliance

After calculating electrical power requirement, it’s important to consider the daily operating time of each device. Some appliances and devices, such as refrigerators, run continuously, while others, such as washing machines and air conditioners, run for a limited time each day. To get a more accurate estimate of your home’s electrical load, you should factor in the operating time of each device.

5. Calculate Electrical Load in Kwh

To calculate the electrical load in Kwh, we need to know the total number of watts used and the number of hours that those watts are used per day as obtained in previous steps. The formula for calculating Kwh is as follows:

Kwh = (Wattage * Usage Hours) / 1000

In this case the electrical load estimate is 65.7 Kwh. It means that a house of 2 bedrooms will consume 65.7 units (Kwh) of electricity in 24 hours. It should be kept in mind that the total electrical load does not exceed 80% of the electrical capacity to avoid overloading.

6. Consider Peak Loads

Peak loads refer to the highest electrical demand that occurs during a certain period. When calculating the electrical load of your home, it’s important to consider peak loads, as they can affect the size of the electrical panel and battery bank you need.

For example, if you use your air conditioner and washing machine at the same time, it will increase your electrical load, so you should factor this in when calculating your home’s electrical load.

7. Electrical Load Estimate for a Building

Similarly, for a building, you can add the electrical loads of all the spaces i.e individual rooms (bedrooms, offices etc), kitchens, washrooms and so on. Most of the buildings are having a similar pattern of these spaces (even floors in most cases). So it’s easy to calculate for one space and then simply multiply for the number of spaces in building to get the electrical load estimate for a building.

C- How to Calculate Electrical Capacity of a Building

To calculate the electrical capacity or maximum power an electrical system can safely handle (measured in kilovolt-amperes, kVA) based on your electrical load of 66 kWh, follow these steps:

8. Convert Electrical Load from kWh to kW

Since electrical capacity is measured in kVA, we need to convert the electrical load from kilowatt-hours (kWh) to kilowatts (kW). The conversion is straightforward:

Electrical Load (kW) = Electrical Load (kWh) / Time (hours)

Given that your electrical load is 66 kWh, we’ll assume it is consumed within a 24-hour period for simplicity:

Electrical Load (kW) = 66 kWh / 24 hours = 2.75 kW

9. Determine the Power Factor

The power factor is a ratio that represents the efficiency of power usage in an electrical system. For residential homes, the power factor is often assumed to be close to 1.0 (or 100%).

10. Calculate Electrical Capacity in kVA

With the electrical load expressed in kilowatts and the power factor close to 1.0, we can now calculate the electrical capacity in kilovolt-amperes (kVA) using the following formula:

Electrical Capacity (kVA) = Electrical Load (kW) / Power Factor

Assuming a power factor of 1.0:

Electrical Capacity (kVA) = 2.75 kW / 1.0 = 2.75 kVA

Therefore, the electrical capacity or maximum power your electrical system can safely handle is 2.75 kilovolt-amperes (kVA). This calculation allows you to assess the capability of your electrical system and ensure it can handle the specified electrical load without overloading, thus providing a safe and efficient power supply.

D- Electrical Capacity Calculation for a Residential Building

Just like in the case of home or general building, calculate electrical load estimate for residential building and follow these steps

Step 1: Convert Electrical Load from kWh to kW

Let’s assume the electrical load for the building is 200 kWh for a 24-hour period:

Electrical Load (kW) = 200 kWh / 24 hours = 8.33 kW

Step 2: Determine the Power Factor

The power factor for buildings can vary but is often assumed to be around 0.9 (or 90%) for commercial and industrial properties.

Step 3: Calculate Electrical Capacity in kVA

Using the formula:

Electrical Capacity (kVA) = Electrical Load (kW) / Power Factor

Assuming a power factor of 0.9:

Electrical Capacity (kVA) = 8.33 kW / 0.9 = 9.26 kVA

Therefore, the electrical capacity or maximum power the building’s electrical system can safely handle is 9.26 kilovolt-amperes (kVA).

E- Electrical Load Calculation for Commercial Building

To calculate the electrical load capacity for a commercial building, follow these steps:

- Determine Electrical Load: Identify the total electrical load of all connected devices and systems within the building. This includes lighting, HVAC systems, machinery, computers, and other electrical equipment.

- Consider Power Factor: For commercial buildings, the power factor typically falls between 0.98 and 0.92. Multiply the total electrical load by the assumed power factor to adjust for the efficiency of power usage.

- Calculate Electrical Load Capacity: Divide the adjusted electrical load by the assumed power factor to determine the electrical load capacity. This result represents the maximum power the building’s electrical system can safely handle, ensuring a safe and reliable power supply.

By considering the power factor and performing these calculations, you can accurately assess the electrical load capacity for a commercial building and ensure its electrical system operates efficiently and safely.

How to Calculate Electrical Load Capacity In A House?

When it comes to managing electricity in your house, understanding how to calculate the electrical load capacity is essential. This process involves determining the total power demand of all appliances and fixtures while maintaining a safety margin. Let’s delve into the steps of this unique and crucial calculation and explore some rule-of-thumb guidelines for different service sizes.

Understanding the Relationship Between Watts, Volts, and Amps

Before we dive into the calculation process, it’s crucial to comprehend the relationship between watts, volts, and amps. These fundamental electrical terms have a mathematical connection that can be expressed in two ways:

- V (Volts) *I (Amps) = P (Watts) whereas V = Voltage, I = Current and P = Power

- I (Amps) = P (Watts)/V (Volts)

Step 1: Individual Circuit Capacity

To begin, let’s calculate the capacity of individual circuits. For instance, consider a 20-amp, 120-volt branch circuit:

| Electrical Term | Calculation | Result |

|---|---|---|

| Watts | 20 amps x 120 volts | 2400 watts |

| Realistic Capacity | 2400 watts x 80% (safety margin) | 1920 watts |

Hence, the circuit’s realistic capacity is 1920 watts to prevent overloads. Ensure that the total power consumption of light fixtures and plug-in appliances on this circuit stays below 1920 watts.

Step 2: Assessing Home’s Overall Electrical Service

Next, let’s determine the capacity of your home’s entire electrical service, typically operating at 240 volts:

| Electrical Term | Calculation | Result |

|---|---|---|

| Watts | 240 volts x 100 amps | 24,000 watts |

| Realistic Capacity | 24,000 watts x 80% (safety margin) | 19,200 watts |

In this example, a 100-amp electrical service should ideally handle a maximum power load of 19,200 watts.

Step 3: Calculating Load

Calculating the actual load involves adding up the wattage ratings of all appliances and fixtures that could potentially draw power simultaneously. While it may seem intuitive to sum up all the wattages, it’s essential to account for the fact that not all devices run simultaneously.

Professional electricians sometimes use an alternative method, as shown below:

- Individual Circuit Capacity: Begin by calculating the capacities of individual circuits, as discussed earlier. This step involves understanding the relationship between watts, volts, and amps to ensure that each circuit can safely handle its designated load.

- Assessing Home’s Overall Electrical Service: Next, determine the capacity of your home’s entire electrical service, typically operating at 240 volts. This assessment takes into account the wattage capacity of each circuit and ensures the overall electrical service can accommodate the combined power demand.

- Accounting for Diversity – Subtract 10,000: To address diversity in power usage, subtract a specific value, usually 10,000 watts, from the total wattage of all appliances and fixtures. This adjustment accounts for the likelihood of not all devices operating at maximum capacity simultaneously, resulting in a more realistic assessment of the overall electrical load.

- Applying a Safety Margin – Multiply by 0.40: To ensure safety and prevent overloading the electrical service, apply a safety margin. This is achieved by multiplying the result from Step 3 by 0.40 (or 40 percent). The safety margin leaves a significant portion of the electrical service’s capacity untapped during regular usage, providing a buffer to handle occasional high-demand situations.

- Balancing Capacity – Add 10,000: After accounting for diversity and applying the safety margin, reintroduce some additional capacity to the calculation. Add 10,000 watts back to the previous result, striking a balance between conservative estimation and practical power demands. This additional capacity caters to regular high-power requirements that may arise during specific activities in the home, ensuring the electrical service can handle such peak loads without issues.

- Consider Air Conditioners and Heating Appliances: Account for the full wattage rating of permanent air conditioners and heating appliances. Then, add the larger of the two values, as heating and cooling operations do not occur simultaneously.

- Divide by 240: Finally, divide the total obtained in previous step by 240.

The resulting value provides the suggested amperage needed to adequately power your home, giving you a comprehensive evaluation of your current electrical service.

Rule-of-Thumb Guidelines

In addition to precise calculations, following rule-of-thumb guidelines can provide a quick estimate of appropriate service sizes:

- 100-amp service: Suitable for small to moderate-sized homes with gas-powered heating appliances.

- 200-amp service: Recommended for homes up to 3,000 square feet with electric appliances and heating/cooling equipment.

- 300-400-amp service: Ideal for larger homes with all-electric appliances and heating/cooling systems exceeding 20,000 watts. This often involves two service panels, with one providing 200 amps and the other 100 or 200 amps.

How Do you Increase the Electrical Load in a House?

If you are considering adding new appliances or electrical devices to your home, it’s essential to understand your electrical system’s capacity to handle the increased load safely. Calculating the electrical load and comparing it to your electrical panel’s capacity will determine if an upgrade is necessary. Let’s take a closer look at the process of increasing electrical load in your house and the considerations involved.

Determining Existing Electrical Load:

To begin, you need to determine the existing electrical load of your home. This involves several steps:

- Measure the exterior dimensions of your home, including any attached garages, and calculate the approximate square footage, excluding open porches and unfinished areas not suitable for future habitable use.

- Determine the power draw for all general lighting and receptacle circuits, as well as circuits supplying major appliances.

- Include 1,500 volt-amperes for each 120-volt 20-amp kitchen circuit and laundry circuit.

- Account for the power rating (in volt-amperes) of all fixed appliances on dedicated circuits, such as your washer/dryer, dishwasher, electric stove, microwave, refrigerator, and water heater. This information can usually be found on the appliance label or in the product specifications online.

- Check the labels on your furnace and air conditioning system for their power ratings. In this case, choose the larger number since these appliances won’t be used simultaneously.

Sample Calculation:

Let’s consider a 2,014 square foot median size US home with the following electrical load breakdown:

- General Lighting and Receptacles: 5,500 VA

- Small Appliance Circuits: 4,000 VA

- Laundry Circuit: 2,500 VA

- Gas Furnace: 2,500 VA

- Microwave Oven: 2,000 VA

- New Electric Water Heater: 3,500 VA

By summing up these values, we get a total existing load of 20,000 VA. Now, to determine the actual electrical capacity required, we apply certain adjustments.

Calculating Electrical Capacity and Load Comparison:

The National Electrical Code (NEC) recommends that the load on the electrical panel should not exceed 80% of its capacity to prevent overloads and overheating. Therefore, the total existing load needs to be adjusted accordingly.

In our sample calculation, the first 12,000 VA (out of the total existing load of 20,000 VA) is considered at 100% capacity. The remaining 8,000 VA (20,000 VA – 12,000 VA) is adjusted to 40% of its value, which equals 3,200 VA. Consequently, the total adjusted existing load is 12,160 VA.

To convert the adjusted load to amperes, divide it by the voltage of your electrical service, typically 240 Volts in most homes. In this case, the adjusted load is 12,160 VA / 240 Volts, which equals 51 Amperes.

Making Informed Decisions:

Once you’ve calculated the load and found it to be within 80% of your panel’s capacity, you can consider adding new appliances without upgrading the panel. However, if the load exceeds the 80% threshold, it is essential to upgrade the panel to ensure the safety and efficiency of your electrical system.

Upgrading the panel involves installing new wiring and can be an expensive project. Therefore, it is advisable to consult with a licensed electrician to explore possible ways to reduce your load or plan for a safe and efficient electrical upgrade. This will help you make informed decisions about increasing the electrical load in your house while ensuring a reliable and secure power supply for your growing electrical needs.

How to estimate the size of generator/solar array from an electrical load

The size of a generator or solar array required to meet an electrical load can be estimated by considering the following factors:

- Total electrical load: This is the total amount of electrical energy required to power all of the appliances and devices in a home or building. The total electrical load can be calculated by summing the wattage of all of the appliances and devices as obtained in previous section.

- Peak load: This is the highest amount of electrical energy required at any one time. For example, if a washing machine and dishwasher are running at the same time, this would represent the peak load.

- Load factor: This is a measure of the average power consumption of a load over a specified period of time. It is calculated by dividing the total energy used over a given period of time by the total energy that would have been used if the load had been at its maximum level for the entire period.

- Capacity factor: This is a measure of the amount of energy produced by a generator or solar array relative to its potential maximum output. It is calculated by dividing the total energy produced over a given period of time by the total energy that would have been produced if the generator or solar array had been operating at full capacity for the entire period.

Based on these factors, the size of a generator or solar array can be estimated as follows:

- For a generator:

- Determine the total electrical load, peak load, and load factor.

- Calculate the generator’s required capacity by multiplying the total electrical load by the load factor.

- Choose a generator with a capacity that meets or exceeds the calculated required capacity. It’s always best to choose a generator with a capacity slightly higher than the calculated required capacity to ensure that it can meet the peak load and provide some margin for unexpected demand.

- For a solar array:

- Determine the total electrical load, peak load, and load factor.

- Calculate the solar array’s required capacity by multiplying the total electrical load by the load factor and dividing by the capacity factor.

- Choose a solar array with a capacity that meets or exceeds the calculated required capacity. It’s always best to choose a solar array with a capacity slightly higher than the calculated required capacity to ensure that it can meet the peak load and provide some margin for unexpected demand.

It’s important to note that these calculations are based on rough estimates, and actual energy requirements may vary based on usage patterns, appliance efficiency, weather conditions, and other factors.

Understand Watts, Volts and Amps

Watts, volts, and amps are all units of measurement used to describe electrical power. Here is a brief overview of each:

- Watts: Watts are a measure of the amount of electrical power being used. The higher the number of watts, the more electricity is being used.

- Volts: Volts are a measure of the electrical potential difference between two points. Higher voltages indicate a greater potential difference, which can result in more electrical power being transmitted.

- Amps: Amps are a measure of the flow of electrical current. The higher the number of amps, the more electrical current is flowing through a circuit.

Understanding the relationships between watts, volts, and amps can be helpful when working with electrical systems and calculating electrical loads. For example, the formula for calculating watts is watts = volts x amps. This means that if you know the voltage and the current flowing through a circuit, you can calculate the watts.

Factors affecting electrical load estimation

To calculate electrical load estimate for a building, you need to consider two main factors:

- The type of building you have (e.g., home, office, warehouse, etc.)

- The number of occupants in the building

– Other factors

-The type of business or businesses that will be using the building

-The hours of operation for each business

-The type and number of electrical devices that will be in use

Demand factor vs diversity factor methods for power requirement estimation

To determine the estimated power requirements for the various types of loads in the building two methods are used: 1- “demand factor”, 2- “diversity factor.”

Demand factor method

Demand factor is a measure of how much of the installed electrical capacity is actually used at any given time. It is used to calculate the expected peak electrical demand for a specific area or time period.

The demand factor is calculated by dividing the average electrical demand by the installed electrical capacity. For example, if a building has an installed electrical capacity of 100 kW and the average electrical demand is 80 kW, the demand factor is 0.8 (80/100).

A demand factor of 1.0 means that the installed electrical capacity is being used at its maximum capacity, while a demand factor of 0.5 means that only half of the installed capacity is being used.

Demand factor is used to determine the required size and capacity of electrical equipment, such as transformers and generators, needed to meet the peak demand of an area or time period. A lower demand factor means that more equipment is needed to meet the peak demand.

For example, if a commercial building has a demand factor of 0.6, it means that 60% of the installed electrical capacity is being used at peak times and 40% is not being used.

Diversity factor method

The diversity factor, also known as the load diversity factor, is a measure of how evenly the electrical load is distributed among different areas or times. It is used to estimate the peak electrical demand for a specific area or time period.

A diversity factor of 1.0 means that all of the electrical load is concentrated at one specific time or in one specific area, while a diversity factor of 0.5 means that the load is evenly distributed among different times or areas.

The diversity factor is used in load calculations to determine the size and capacity of electrical equipment, such as transformers and generators, needed to meet the peak demand of an area or time period. A higher diversity factor means that less equipment is needed to meet the peak demand.

For example, if a commercial building has a diversity factor of 0.6, it means that 60% of the electrical load is concentrated at peak times and 40% is distributed evenly throughout the day.

Once you have determined the demand factors and/or diversity factors for all of the different types of loads in your building, you can then use these factors to calculate an estimate of your electrical power requirements. To do this, simply multiply the total connected load (in watts or kilowatts) for each type of load by its respective demand factor or diversity factor. This will give you an estimate of how much power (in watts or kilowatts) each type of load is expected to require at any given time.

How to calculate electrical load for individual rooms and areas

To calculate electrical load for individual rooms and areas in a building, you will need to consider the wattage ratings of all of the appliances and equipment being used. Start by adding up the wattage ratings for all of the permanent appliances, such as the refrigerator, oven, and water heater.

Then, add in any space heaters or other plug-in appliances that may be used on a regular basis. Finally, don’t forget to include all of the light fixtures and plug-in outlet circuits in the calculation.

Calculating the total electrical load for your building

To calculate total electrical load for your building, you will need to add up the wattage ratings for all of the permanent appliances and equipment being used, as well as any space heaters or other plug-in appliances that may be used on a regular basis. Don’t forget to include all of the light fixtures and plug-in outlet circuits in your calculation.

Once you have determined the total wattage, you can consult with an electrician to determine the appropriate size for your electrical service panel and to ensure that your building’s electrical system is properly designed and sized.

What to do if your electrical load estimate exceeds the capacity of your service panel

If your electrical load estimate exceeds the capacity of your service panel, it is important to take steps to address the issue. One option is to upgrade to a larger service panel with more capacity. Alternatively, you may be able to reduce the electrical load by removing or replacing some of the appliances or equipment being used. It is important to work with a qualified electrician to determine the best solution for your specific situation.

Why is electrical load calculation important?

Electrical load calculation is important for several reasons:

- Safety: Properly calculating the electrical load for a building ensures that the electrical system is properly designed and sized to meet the needs of the occupants. If the electrical load is not properly calculated, it can lead to issues such as overloaded circuits, power outages, and even fires.

- Energy efficiency: Accurate electrical load calculation can help to ensure that the electrical system is not unnecessarily over-designed, which can lead to higher energy costs.

- Cost effectiveness: Properly calculating the electrical load can help to ensure that the electrical system is appropriately sized, which can help to minimize the cost of installation and maintenance.

- Code compliance: Building codes often have requirements for the electrical load of a building, and proper electrical load calculation is necessary to ensure compliance with these codes.

Overall, electrical load calculation is an important step in the planning and design of any building’s electrical system. It helps to ensure the safety, energy efficiency, cost effectiveness, and code compliance of the electrical system.

Common Mistakes to Avoid When Calculating Electrical Load

Here are some common mistakes to avoid when calculating electrical load:

- Not accounting for all the devices: One of the most common mistakes when calculating electrical load is not accounting for all the devices that will be connected to the electrical system. Make sure to include all appliances, electronics, and other electrical devices that will be used.

- Underestimating the load: Another mistake is underestimating the electrical load. This can result in overloading the electrical system, which can cause electrical fires or damage to the devices. Always err on the side of caution and overestimate the load.

- Not considering the duty cycle: Many devices have a duty cycle, which is the amount of time they are used in a day. Failure to account for this can lead to an inaccurate calculation of the electrical load.

- Not factoring in the power factor: The power factor is a measure of how efficiently electrical power is used. Failing to account for this can result in an overestimation or underestimation of the electrical load.

- Ignoring safety codes: Electrical codes are in place for safety reasons. Ignoring them can result in serious safety hazards. Make sure to follow all safety codes when calculating electrical load.

By avoiding these common mistakes, you can ensure a more accurate calculation of the electrical load and a safer and more efficient electrical system.

Methods used for calculating electrical load estimate

Determining the total electrical load for a building is vital for ensuring that the structure has the capacity to support everyone’s needs. There are a few different ways to estimate the amount of electricity required, but some methods are more accurate than others.

– Building square footage method

One way to calculate electrical load estimate is to use the square footage of the building. This method is not as accurate as other methods, but it can be a good starting point. To calculate electrical load using this method, multiply the square footage of the building by 3. This will give you a rough estimate of the minimum amount of electricity required.

– Building number of occupant method

Another way to estimate the electrical load is to use the number of occupants in the building. This method is more accurate than using square footage, but it can still be subject to error. To calculate electrical load using this method, multiply the number of occupants by 10. This will give you a rough estimate of the minimum amount of electricity required.

– Energy consumption data method

The most accurate way to calculate electrical load estimate is to use actual energy consumption data. This data can be obtained from utility bills or other records. If you have access to this data, you can use it to calculate an estimate with high accuracy.

Conclusion

In conclusion, calculating the electrical load estimate for a building is a critical step in ensuring that the electrical system is designed and installed correctly. It provides a clear understanding of the energy requirements of the building and helps in determining the appropriate size of the electrical service, the number and type of electrical panels, and the size of conductors and overcurrent protection devices.

The process of calculating electrical load estimate requires careful attention to detail, including a thorough evaluation of the building’s electrical appliances and devices, and a consideration of the expected usage patterns. By taking the time to properly calculate the electrical load estimate, building owners and electrical contractors can ensure that the electrical system is safe, efficient, and capable of meeting the building’s energy demands for years to come.

FAQs

Q: What is the formula for calculating load?

A: The formula for calculating electrical load is:

Power (in watts) = Voltage (in volts) x Current (in amps)

This formula is used to calculate the power required by an electrical device, which is then used to determine the overall electrical load of a system. It is important to ensure that the total electrical load of a system does not exceed the capacity of the electrical system to prevent overloading and potential hazards.

Q: How do you calculate electrical load in kW?

To calculate electrical load in kW (kilowatts), you need to multiply the voltage (V) by the current (I) and then divide the result by 1000.

The formula for calculating electrical load is: P = VI/1000

where P is the power in kW, V is the voltage in volts, and I is the current in amps. This calculation is important for ensuring that the electrical system is not overloaded and can handle the power demand of all connected devices.

Q: How is electrical load calculation done?

A: Electrical load calculation is typically done by adding up the power consumption of all the devices that will be connected to the electrical system. This can include appliances, electronics, lighting, and other electrical devices.

The calculation takes into account the voltage and amperage requirements of each device, as well as the duty cycle and power factor. It’s important to accurately calculate the electrical load to prevent overloading the system and ensure safe and efficient operation.

Q: How do you measure electrical loads?

A: To measure electrical loads, you need to use a device called a power meter or a multimeter. A power meter measures the amount of electrical energy being used by a device or an entire electrical system.

A multimeter can measure both voltage and current, which are necessary for calculating the electrical load. Simply connect the meter to the device or electrical system you want to measure and read the results.

Q: What is KVA to kW?

A: KVA (kilovolt-ampere) and kW (kilowatt) are units of power. KVA represents the apparent power in an electrical circuit, while kW represents the actual power.

The conversion between KVA and kW depends on the power factor of the electrical system. In general, the formula to convert KVA to kW is to multiply KVA by the power factor.

Q: What is the load of 1.5 ton AC in kW?

A: The load of a 1.5 ton AC in kW depends on the specific model and efficiency rating of the air conditioner. As a general rule of thumb, 1 ton of cooling requires 3.5 kW of power, so a 1.5 ton AC would require approximately 5.25 kW of power.

However, it is important to check the manufacturer’s specifications to get a more accurate measurement of the AC’s load.

thanks Engr. Liaqat H., for imparting comprehensive relevant information on the topic.

Thanks Moin for your kind feedback.