Everyone should know some basics on the different types of fire extinguishers and how to use them effectively because the selection of the right type of fire extinguisher can save the lives of your loved ones. The best way to keep everyone safe is to install fire extinguishers around your home or office, and save lives by preventing or controlling fire at an early stage.

In this blog we will cover different types of fire extinguishers and the types of fire they tackle, how they work and the areas/locations they are suitable for. There are many types of fire extinguishers available on the market, and each is designed to tackle different types of fires.

According to survey conducted by technicians of the companies in the UK’s four main trade associations, an increase of 93% in 2021 as compared to 80% in 2003, of fires extinguished using different types of fire extinguishers have been reported. This clearly shows the increasing demand and importance of portable fire extinguishers.

According to Occupational Safety and Health Administration (OSHA), there are basically 5 classes (Class A, Class B, Class C, Class D and Class K) of fires. Following is the classification of types of fire extinguishers based on the class of fire they extinguish.

Classes of Fire and Their Extinguishers

Class A: Ordinary Combustibles

One of the most common class of fire is Class A: Ordinary Combustibles.

Types of Fire Class A Extinguishers Tackle

Class A fire extinguishers are specifically designed to fight fires caused by ordinary combustibles, such as wood, paper, plastic, and textiles. They are best suited for small fires that have not yet spread beyond their initial ignition point. 31% fires in the UK were caused by ordinary combustibles, According to survey by FETA and IFEDA (2015), making it the second major cause of fires after the fires caused by electrical equipments.

How Class A Fire Extinguishers Work?

These fire extinguishers work by spraying a fine mist or foam onto the burning material. The foam helps to smother the flames and prevent them from spreading, while the mist coats the material and helps prevent re-ignition.

Suitable Areas and Locations for Class A Extinguishers

If you have an area of your home or workplace that is prone to fires caused by ordinary combustibles, then a Class A fire extinguisher is an essential addition. Make sure that all occupants of your building are familiar with how to use it and where it is located.

Class B: Flammable Liquids

Types of Fire Class B Extinguishers Tackle

Class B fire extinguishers are designed to extinguish fires involving flammable liquids such as gasoline, oil, paint, and grease. These liquids are usually in the form of liquid fuel, oil, or other combustible liquids. These types of fires can be particularly dangerous as they can quickly spread and lead to a larger disaster.

How Class B Extinguishers Work?

Class B fire extinguishers work by creating a barrier between the fire and the fuel source. Class B fire extinguishers use a chemical foam or powder agent to quickly break down the liquid fuel, depriving it of oxygen and preventing the flames from spreading.

Suitable Areas and Locations for Class B Extinguishers

Class B extinguishers are commonly found in warehouses, factories and other industrial facilities where flammable liquids are present. They are also suitable for garages, and any other locations where flammable liquids are stored and used.

2 Types or Varieties of Class B fire extinguishers

Class B fire extinguishers typically come in two varieties: chemical foam and dry powder.

Chemical foam extinguishers contain a combination of chemicals that, when mixed with water, create a foam that smothers the fire by blocking its access to oxygen.

Dry powder extinguishers use an inert dry powder agent that is designed to smother the fire by forming a layer over the burning liquid.

Class C: Energized Electrical Equipment

Types of Fire Class C Extinguishers Tackle

Class C fire extinguishers are specifically designed to tackle fires that involve energized electrical equipment such as computers, appliances, and wiring. These types of fires can be caused by malfunctions, short-circuits, or other electrical issues, and can be particularly dangerous due to the risk of electrocution. These types of fires are often caused by common electrical problems such as short circuits or overloaded circuits. According to survey by FETA and IFEDA (2015), 43.6% fires in UK are caused by electrical equipments. This makes them the major cause of fires that needs to be extinguished.

How Class C Extinguishers Work?

Class C extinguishers work by interrupting the electrical current, which helps to prevent the fire from spreading and making it easier to put out. Class C extinguishers contain non-conductive liquids, such as carbon dioxide, which will not conduct electricity and therefore can safely be used on energized electrical equipment. The most common type of Class C fire extinguisher is a CO2 extinguisher, which is ideal for smothering fires involving electrical equipment.

Suitable Areas and Locations for Class C Extinguishers

Class C extinguishers are commonly found in offices, schools, factories, warehouses, and other industrial facilities and commercial buildings where electrical equipment is in use. It is important to note that it is best practice to have a Class C extinguisher on hand in any location where an electrical fire could occur, as electrical fires can quickly spread and become more dangerous.

Class D: Combustible Metals

Types of Fires Class D Extinguishers Tackle

Class D fire extinguishers are specifically designed to tackle fires that involve flammable metals such as magnesium, titanium, or potassium. These types of fires are generally found in industrial settings, where flammable metals are used in manufacturing or laboratory processes. These types of fires are particularly hazardous because they can easily spread and emit toxic fumes.

How Class D Extinguishers Work

Class D extinguishers contain a dry powder, such as graphite, sodium chloride, or copper-based agents. This dry powder smothers the fire, cutting off the oxygen supply and preventing it from spreading further. When using a Class D fire extinguisher, it’s important to remember to stand back and aim at the base of the fire, where the flames originate. Aiming at the center of the fire will cause the powder to disperse too quickly and may not be effective in suppressing the flames.

Suitable Areas and Locations

Class D extinguishers are commonly found in laboratories, factories, and other industrial facilities where flammable metals are used. They are particularly useful in settings where traditional fire extinguishers may not be effective, such as in areas where electrical equipment is present. It is important to have a class D extinguisher in these facilities as they are specifically designed to tackle the type of fires that occur in these settings.

Class K: Cooking Oils and Greases

Types of Fire Class K Extinguishers Tackle

Class K fire extinguishers are designed to combat fires that involve cooking oils, greases and fats, such as those found in commercial kitchens. These types of fires can be particularly dangerous as they can quickly spread and become uncontrollable. Class K extinguishers are a crucial piece of safety equipment for any kitchen, whether it be in a restaurant, hotel, or other food service establishment.

How Class K Extinguishers Work

Class K fire extinguishers are filled with a potassium acetate-based dry chemical agent that is designed to smother burning cooking oils and greases. This agent is effective at cooling the burning materials and creating a seal over them, which cuts off the oxygen supply that fuels the fire. Class K fire extinguishers can quickly put out any fires that start in or around cooking oils or greases.

Suitable Areas and Locations for Class K Extinguishers

Class K fire extinguishers are most commonly found in commercial kitchens, such as those found in restaurants, hotels, and other food service establishments. These areas are most at risk of cooking oil and fat fires, and having a Class K extinguisher on hand can be crucial in preventing a small fire from turning into a major disaster. Additionally, it is important to ensure that all employees are properly trained on how to use a Class K extinguisher in case of an emergency.

| Fire Class | Extinguisher Type | Limitation of Extinguisher |

|---|---|---|

| A, B, C | Dry Chemical (multipurpose) | • Generally useful when used in the roofing sector |

| B | Foam—alcohol-resistant and aqueous film-forming foam (AFFF) types | • Costly • Useful on Class B • Short shelf life • Typically not required in the roofing sector |

| A | Water | • Most effective only for Class A fires |

| D | Metal X | • Costly • Keeping it dry is necessary • Not effective on Class A, B, C • Typically not required in the roofing sector |

| B, C | Carbon Dioxide | • Produce oxygen deficiency in confined spaces • Ineffective in windy situations • Can produce frostbite during discharge • Typically not required in the roofing sector |

| B, C | Halon | • Costly • Ineffective in windy situations • Due to disintegration in very hot fires, hazardous gases could be emitted • Typically not required in the roofing sector |

| K | Potassium Acetate | • Costly |

Types of Fire Extinguisher

When it comes to types of fire extinguishers, there are several choices to choose from, each designed to tackle different types of fires. Now we will take a closer look at the five main types of fire extinguishers: Dry Chemical (Powder), C02, Water, Foam and wet chemical extinguishers. Fire Blanket and Gas (Halon) Extinguisher will also be covered.

1- Dry Chemical Fire Extinguisher or Powder Fire Extinguisher

Dry chemical extinguishers are a popular choice among the types of fire extinguishers for tackling fires caused by flammable liquids and gases, as well as electrical equipment fires. Dry chemical extinguishers use a fine dust to smother fires by covering the fuel source and cutting off its access to oxygen. The powder also disrupts the chemical process of combustion, making it an efficient and effective way to extinguish flames.

They are mostly known as “ABC” extinguishers as they can be used on all types of fires. However, they can leave a messy residue and should not be used on cooking fires or deep fat fryers. These extinguishers are often colored yellow because they are filled with fine yellow powder and has monoammonium phosphate as a major component.

Dry chemical extinguishers come in different varieties and can be identified by their label.

| Type | Label | Capabilities |

|---|---|---|

| Dry Chem | DC | Extinguishes Class B and C fires |

| Multipurpose | ABC | Extinguishes Class A, B, and C fires |

| Specialty | BC | Extinguishes Class B and C fires |

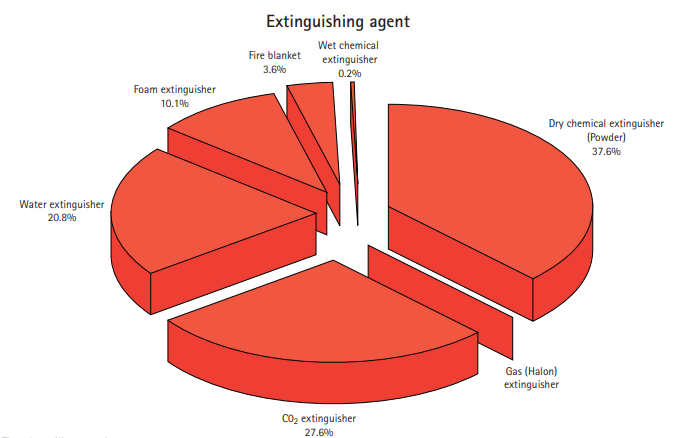

These powder fire extinguishers are pressurized using nitrogen. According to survey by FETA and IFEDA (2015), they extinguish 37.6% fires in UK.

2- C02 Fire Extinguisher

Carbon dioxide (CO2) fire extinguishers are ideal for extinguishing fires caused by electrical equipment, as they do not conduct electricity and leave no residue. As the name suggests, they are filled with a non-flammable gas carbon dioxide. This gas is kept under intense pressure inside the extinguisher, and can be recognized by its distinct horn-like nozzle, which is different from other extinguishers that come with a pressure gauge.

Carbon dioxide puts out fires by replacing the oxygen that the fire needs to burn. It also has a cooling effect on the fuel, making it harder for the fire to continue burning.

When using a CO2 extinguisher, you may notice small pieces of dry ice coming out of the nozzle due to the high pressure. These extinguishers come in a red color and are available in different sizes, ranging from compact 5 pounds containers to larger 100 pounds or bigger. In the larger sizes, the nozzle is attached to a long and flexible hose, making it easy to reach remote places.

CO2 extinguishers are meant to be used on fires that involve flammable liquids or electrical equipment, classified as Class B and C. Carbon dioxide extinguishers may not be effective in putting out Class A fires because they may not be able to reduce the amount of oxygen in the area enough to stop the fire from burning.

They are typically more expensive than other types of extinguishers and are not suitable for use on cooking fires or deep fat fryers. According to survey by FETA and IFEDA (2015), they helped in extinguishing 27.6% fires in UK.

3- Water Fire Extinguisher

Water extinguishers are the simplest and most common among the types of fire extinguishers, and are only used for Class A fires. They work by spraying water from the nozzle, which helps to cover a larger surface area. They are suitable for use on fires caused by ignited paper, wood, straw, coal, rubber, solid plastics and soft furnishings (Class A). They are around 2 feet high and have a weight of roughly 25 pounds when fully filled.

It is not safe to use water to put out fires caused by flammable liquids. Using water can actually make the fire worse instead of putting it out. Additionally, never use water to extinguish an electrical fire. Water can conduct electricity, which poses a risk of electrocution. Before using a water extinguisher on electrical equipment, it is important to unplug it and make sure it is not still receiving power.

According to a survey conducted by the Fire Extinguisher Trade Association (FETA) and the Independent Fire Engineering and Distributors Association (IFEDA) in 2015, it was reported that water extinguishers were used to put out 20.8% of fires in the United Kingdom.

4- Foam Fire Extinguisher

Foam extinguishers are suitable for use on Class A and B fires, and work by releasing a foam that smothers the fire and cools the burning materials. They are often used in kitchens and other areas where cooking oils and fats may catch fire. They are typically more expensive than other types of fire extinguishers and can leave a messy residue. They extinguished 10.1% fires in UK, according to survey conducted by FETA and IFEDA (2015).

5- Wet Chemical Fire Extinguisher

Wet chemical fire extinguishers are designed to be used on fires involving cooking oils and fats. They work by releasing a stream of specially-formulated wet chemical that cools the burning oil and creates a barrier between the fuel and the oxygen, helping to extinguish the fire.

6- Gas (Halon) Fire Extinguisher

Gas (Halon) fire extinguishers work by releasing a gas that smothers the fire and reduces the oxygen supply. They are often used in areas where electrical equipment is present, as they do not conduct electricity and leave no residue. However, they are no longer manufactured due to their negative impact on the ozone layer. Alternative types of fire extinguishers such as CO2 extinguishers should be used instead.

Fire Blanket

Fire blankets are not included in the types of fire extinguishers but still they are a simple and effective way to extinguish small fires, particularly those caused by cooking oils and fats. They work by smothering the fire, reducing the oxygen supply and extinguishing the flames. They are often used in kitchens and other areas where cooking oils and fats may catch fire. They are typically less expensive than other types of extinguishers and are easy to use.

OSHA Fire Extinguisher Regulations

The Occupational Safety and Health Administration (OSHA) has strict regulations in place for fire protection and prevention in the workplace. These regulations can be found mainly in Subpart F of the construction standards, and they apply to all employers to ensure a safe working environment. Roofing contractors, in particular, are required to follow specific regulations when it comes to different types of fire extinguishers and fire prevention.

The following sections of the construction standards contain requirements for fire protection that are of significance to roofing contractors:

1926.24 Subpart C, Fire protection and prevention programs

1926.150 Fire protection

1926.151 Fire prevention

1926.152 Flammable and combustible liquids

1926.153 Liquefied petroleum gas (LP-Gas)

1926.154 Temporary heating devices

One of the key regulations for roofing contractors is the requirement to have a minimum-rated 10B fire extinguisher within 50 feet of any point of job site use of more than 5 gallons of flammable or combustible liquids or 5 pounds of flammable gas. Roofing contractors typically purchase dry-chemical fire extinguishers because they can extinguish three fire classes (A, B and C). These extinguishers must be rated by a nationally recognized testing laboratory and must be inspected and maintained on a regular basis.

PASS in using Fire Extinguishers

When using fire extinguishers, employees should use the “PASS” system of early-stage firefighting, which includes:

P: Pulling the pin

A: Aiming at the base of the fire

S: Squeezing the handle

S: Sweeping at the fire from side to side

If a fire cannot be extinguished using one full extinguisher, employees should evacuate the site and let the fire department handle the situation.

Fire prevention is another important aspect of OSHA regulations for roofing contractors. Fire prevention requires segregating the three elements of the fire triangle, and in practice, this can be achieved by posting and enforcing no-smoking signs around flammable liquids and gases and having fire watches on all work involving torch-applied materials of a minimum of two hours after the last torch is turned off.

Proper storage and handling of flammable and combustible liquids is also crucial for fire prevention. Only approved, closed containers for storage of flammable or combustible liquids may be used under OSHA rules. Such containers include safety cans or containers approved by the U.S. Department of Transportation. A safety can is a container that has a self-closing lid, internal-pressure relief, and flame arrestor with a capacity of not more than 5 gallons. Inexpensive, plastic cans without these features are not approved for use in roofing operations.

In addition, it is important to dissipate static electricity when handling flammable and combustible materials. When transferring flammable or combustible liquids from one container to another, the two containers must be “bonded” together. The bonding process involves attaching a wire with alligator clips on each end to both containers. The clips must penetrate the container coating and touch metal.

Overall, OSHA regulations for fire protection and prevention in the workplace are crucial for ensuring a safe working environment for roofing contractors and other employers. Employers must comply with these regulations by providing appropriate fire extinguishers, implementing fire prevention measures, and ensuring proper storage and handling of flammable and combustible liquids.

Final Words on Fire Extinguishers

Fire extinguishers are an essential part of any home or business fire safety plan. While they can help save lives and property, it’s important to know the pros and cons of each type before purchasing one for your space.

There are several different types of fire extinguishers available, each designed for use in different scenarios. The most common types include water, foam, powder, and carbon dioxide fire extinguishers. Water-based extinguishers are typically used on Class A fires (those involving solids such as wood, paper, plastics, etc.). They can also be used on Class B fires (flammable liquids such as gasoline) but should never be used on Class C fires (electrical fires). Foam-based extinguishers work well on all classes of fires but do not work when dealing with energized electrical equipment. Powder-based extinguishers work well with combustible metals like magnesium and titanium and should never be used on a grease fire because the powder makes the oil slick even more dangerous. Carbon dioxide is good for combustible metal fires but does not work well on other types of burning materials.

Dry chemical is another type that works well against all classes of fires including energized electrical equipment, making it a great choice if you have a need to protect computer equipment from being damaged by smoke or sparks coming from a nearby fire.